Are you wondering what work-hardened copper is and why it’s so often mentioned in various fields? This article will shed light on this material with unique properties. We will explore its definition, its distinctive characteristics, how it behaves during bending, and where you will most often encounter it. Prepare to discover the fascinating world of work-hardened copper.

Key Takeaways

- Work-hardened copper is pure copper that has been mechanically worked, making its structure harder and stronger than annealed copper.

- Its exceptional properties include excellent electrical and thermal conductivity, as well as good corrosion resistance.

- Bending work-hardened copper requires specific techniques to avoid breakage, as it is less malleable than annealed copper.

- It is found in various applications such as plumbing, electrical work, and even architecture for its durability and appearance.

- Although stronger, work-hardened copper can be more difficult to work with than other materials, which influences its cost and implementation.

Definition and Characteristics of Work-Hardened Copper

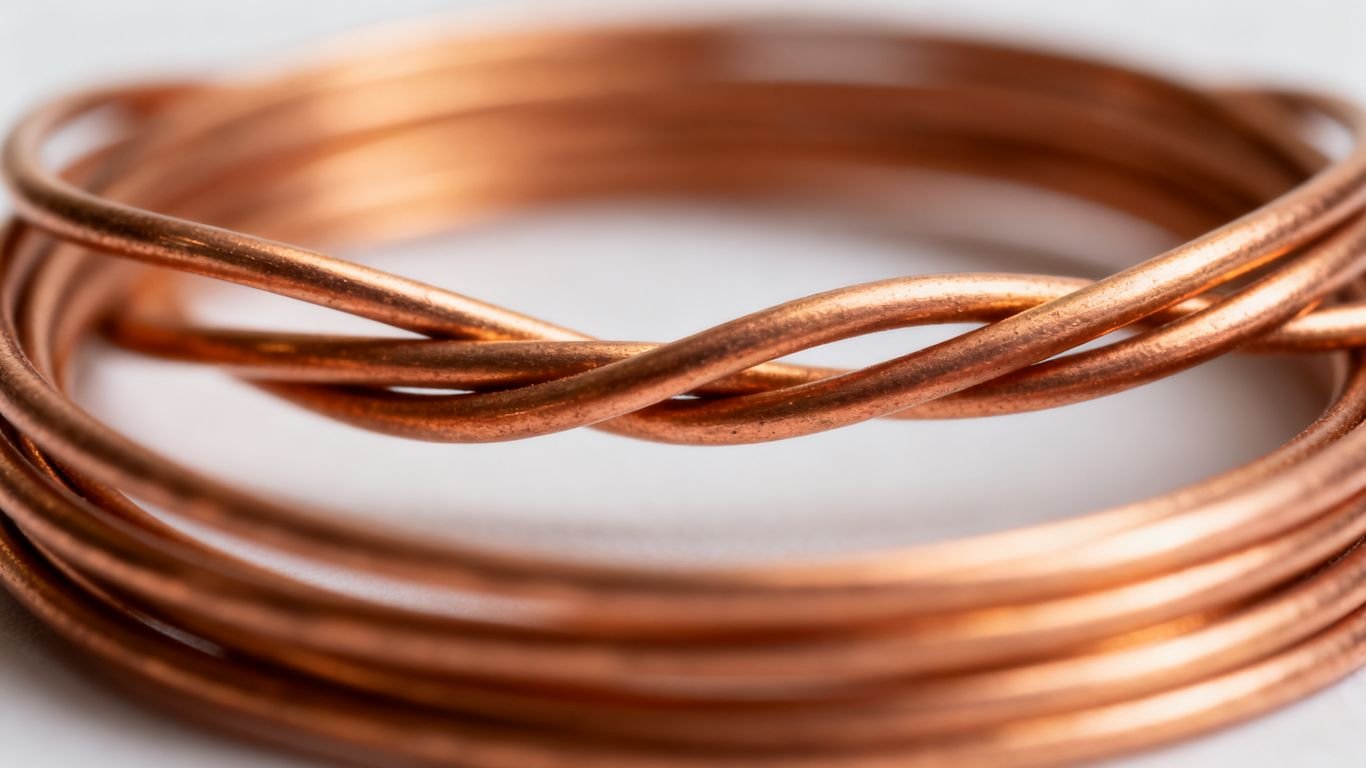

Work-hardened copper, you see, is copper that has undergone cold mechanical treatment. Imagine it being worked, deformed without being heated. This process, called work hardening, changes quite a few things in its internal structure. It makes it harder and stronger than before. It’s a bit like forging it by force, without fire or heat. This method gives it mechanical properties very different from those of copper in its original, so-called annealed, state.

Nature of Work-Hardened Copper

Simply put, work-hardened copper is a metal that has been hardened by cold mechanical deformation. It’s not an alloy, but pure copper, often over 99.9%, that has been shaped. This treatment modifies its crystalline structure, creating defects that block the movement of dislocations. This is what gives it its increased strength. It is often found in the form of tubes, wires, or sheets that have already been worked. It’s a bit like a metal that has already had a first life of transformation before arriving at your home. If you are looking for information on this process, you can consult the definition of work-hardened.

Distinctive Mechanical Properties

Work hardening has quite marked effects on copper. Its tensile strength increases, as does its hardness. It becomes less ductile, meaning it is more difficult to stretch without it breaking, and also less malleable, meaning it deforms less easily under impact or hammering. Here’s a brief overview:

- Tensile Strength: Increased compared to annealed copper.

- Hardness: Significantly higher.

- Ductility: Decreased, it is more brittle.

- Malleability: Reduced, it resists deformation better.

These properties mean that work-hardened copper is preferred when a material is needed that retains its shape and better resists stress, without losing all its intrinsic qualities.

Comparison with Annealed Copper

It is important to clearly distinguish work-hardened copper from its cousin, annealed copper. Annealed copper is copper in its softest and most malleable state. It is obtained after heat treatment that softens the metal and restores its crystalline structure. It is the ideal material for complex shapes and repeated bending. Work-hardened copper, on the other hand, is the result of mechanical work that makes it more robust but also more rigid. Think of it like this:

- Annealed Copper: Soft, very ductile, easy to form, but less strong. Ideal for fine electrical wires or very elaborate shapes.

- Work-Hardened Copper: Harder, stronger, less ductile, retains its shape better. Perfect for plumbing pipes that need to stay straight or parts subjected to stress.

The choice between the two will therefore depend entirely on the intended use. Work-hardened copper is often used in applications where dimensional stability and mechanical strength are paramount.

Physical and Chemical Properties of Copper

Copper, this multifaceted metal, possesses physical and chemical characteristics that make it particularly interesting for many applications. You might be wondering what sets it apart from other metals? Let’s look at its advantages.

Exceptional Electrical and Thermal Conductivity

One of copper’s most remarkable properties is its ability to conduct electricity and heat. It is the second-best electrical conductor after silver. This exceptional performance makes it a material of choice for electrical wiring, printed circuit boards, and electronic components. Its thermal conductivity is also very high, making it ideal for heat exchangers, radiators, and cookware. This efficiency in energy transfer is a major advantage in many systems.

Here’s a comparative overview:

| Property | Copper (annealed pure) | Brass (typical) | Unit |

|---|---|---|---|

| Electrical Conductivity | 100 % IACS | 25-40 % IACS | % IACS |

| Thermal Conductivity | ~401 | ~120 | W/(m·K) |

This difference in conductivity is a determining factor in choosing the material for specific applications. For high-performance electrical systems, copper remains the standard.

Inherent Ductility and Malleability

Copper is distinguished by its high ductility and malleability. This means it can be drawn into fine wires without breaking and can be hammered or rolled into thin sheets. This flexibility greatly facilitates its shaping and working. This is why you find it in fine electrical wires or plumbing pipes that need to be bent. This ability to be shaped without losing its properties is a major asset.

The ease with which copper can be deformed without cracking is a key characteristic. It allows for the creation of complex shapes and precise assemblies, which is often necessary in technical installations.

Corrosion Resistance and Patina Formation

Copper has good corrosion resistance, especially in many environments. In contact with air and moisture, it gradually develops a protective layer called a patina. This patina, often a characteristic blue-green colour, does not harm the material but protects it from deeper degradation. It acts as a natural barrier. This aesthetic transformation, although slow, is a signature of copper and can be sought after in architectural applications. It testifies to the material’s longevity. Air conditioning systems, for example, use refrigerants that must be contained without degradation, and copper’s resistance is an advantage here for the proper functioning of the systems.

It is important to note that copper’s behaviour in the face of corrosion can vary depending on the environment. For example, in certain sanitary installations, care must be taken with contact with other metals to avoid undesirable electrochemical reactions.

The Work-Hardening Copper Bending Process

Work-hardened copper, although more rigid than its annealed counterpart, can be shaped by bending to adapt to various configurations. This operation requires a certain technique to avoid deforming or cracking the material.

Bending Techniques and Tools

To bend work-hardened copper, several methods are available. The choice will depend on the diameter of the tube, the desired bending angle, and the precision required. The most common tool is a manual pipe bender, which uses a template to guide the curve. For small diameters, a simple internal bending spring may be sufficient to prevent the tube from collapsing during the operation. For larger jobs or complex shapes, hydraulic or powered pipe benders are available.

- Manual Pipe Benders: Ideal for standard installations, they offer good control.

- Bending Springs: Useful for small diameter tubes to maintain their shape.

- Professional Pipe Benders: Necessary for large diameters and tight bending radii.

It is essential to choose the right tool to ensure a clean and damage-free result.

Parameters Influencing Deformation

Several factors play a role in how work-hardened copper deforms during bending. The bending radius is crucial: too small a radius will increase the risk of breakage. The speed at which you apply force is also important; too sudden a movement can lead to uneven deformation. Ambient temperature can also have a slight influence on copper’s malleability.

Challenges and Solutions for Precise Bending

The main challenge with work-hardened copper is achieving a precise angle without flattening the tube or creating unsightly kinks. Tube flattening is a common problem, especially on tight bends. To overcome this, the use of an internal mandrel or a bending spring is highly recommended. If you notice slight deformation, localised annealing can sometimes help restore some of the copper’s flexibility, but this must be done carefully to avoid weakening the metal.

Bending work-hardened copper requires patience and practice. It is often best to test on a scrap piece of tube to master the technique and check the material’s behaviour before working on your final piece. Good tool preparation and an understanding of the material’s limitations are your best allies.

Common Applications of Work-Hardened Copper

Plumbing and Heating Systems

Work-hardened copper is a material of choice for plumbing and heating installations. Its corrosion resistance, durability, and ability to withstand high temperatures and pressures make it an ideal candidate for potable water networks, central heating circuits, and hot water production systems.

- Exceptional Durability: You benefit from remarkable longevity, reducing the risk of leaks and frequent replacements.

- Hygiene: Copper does not promote bacterial growth, which is a major advantage for drinking water.

- Ease of Installation: Although more rigid than annealed copper, work-hardened copper can be bent with appropriate tools, allowing for custom installations.

- Compatibility: It pairs well with various types of fittings, whether soldered, crimped, or compression.

In heating systems, copper’s ability to conduct heat contributes to efficient temperature distribution throughout the building. Its resistance to thermal cycles ensures consistent performance over the years.

Electrical and Electronic Applications

Thanks to its excellent electrical conductivity, work-hardened copper is indispensable in the electrical field. It is used for cables, busbars, transformers, and many electronic components where efficient energy transmission is paramount.

- Superior Conductivity: It is one of the best conductors, second only to silver, which minimises energy loss.

- Reliability: Its resistance to oxidation and thermal stability ensure safe and durable electrical connections.

- Safety: It helps prevent overheating and fire risks associated with less efficient materials.

Architectural and Decorative Uses

Beyond its functional aspects, work-hardened copper finds its place in architecture and decoration. Its warm hue and its ability to develop a unique patina over time give it a particular aesthetic appeal.

- Evolving Aesthetics: The green patina that forms over time adds character to buildings and objects.

- Varied Applications: It is found in roofing, facades, gutters, interior decorative elements, lighting fixtures, and even works of art.

- Longevity: It withstands weathering well, making it suitable for long-term outdoor applications.

Advantages and Limitations of Work-Hardened Copper

Work-hardened copper, while presenting undeniable advantages, is not without certain constraints that are good to know before adopting it for your projects.

Advantages in Terms of Durability and Performance

One of the main attractions of work-hardened copper lies in its exceptional durability. This metal, once work-hardened, gains mechanical strength, making it more capable of withstanding stress. Its corrosion resistance is also a major advantage; it develops a protective patina that preserves it from external aggressions in the long term. This characteristic is particularly appreciated in plumbing and heating installations, where longevity is paramount. Furthermore, its thermal and electrical conductivity, although slightly lower than that of pure annealed copper, remains very high, making it a wise choice for many technical applications. Its ability to withstand high temperatures without deforming is also a notable strong point.

Cost and Implementation Considerations

It must be acknowledged that work-hardened copper represents a higher initial investment than some other materials. Its cost can be a barrier, especially for large-scale projects. Implementation also requires careful attention. Although its ductility is less than that of annealed copper, bending work-hardened copper requires appropriate tools to avoid excessive deformation or breakage. It is therefore important to have the right tools and know-how to work with this material, which may involve additional labour costs. For example, for tight bends, the use of a bending spring or a hydraulic pipe bender is often necessary to preserve the integrity of the tube. Soldering or brazing techniques also require skill to ensure leak-proof and strong joints.

Comparison with Other Metallic Materials

Compared to materials like brass or steel, work-hardened copper offers a unique balance. Brass, for example, is harder and more wear-resistant, but its conductivity is much lower, making it less suitable for demanding electrical or thermal applications. Steel, on the other hand, can be more economical and mechanically stronger in certain conditions, but it is much more prone to corrosion, often requiring protective coatings. Work-hardened copper stands out for its inherent corrosion resistance, good conductivity, and relative ease of implementation once the techniques are mastered. It is often preferred for piping systems where water purity is a concern, as it does not react chemically in a harmful way. For architectural applications, its ability to develop an aesthetic patina makes it unique, unlike steel which can rust unattractively or brass which can tarnish differently. The choice will therefore depend heavily on the specific requirements of your project, whether it be plumbing, electrical, or architectural design.

Work-hardened copper is a material of choice for applications requiring good mechanical strength and unwavering durability. Its implementation requires a thoughtful approach, but the benefits in terms of performance and longevity are often considerable, placing it advantageously against other common metals like brass or steel for many uses, particularly in water conveyance.

Conclusion on Work-Hardened Copper

So, we have explored together what work-hardened copper is, its particular properties, how it is worked, especially for bending, and where it finds its use. You have seen that it is not just ordinary copper; its work-hardened state gives it increased strength, which is very practical for certain applications. But be careful, this hardness also makes the work more delicate, especially if you want to make curves. It sometimes needs to be heated a little to make it more flexible, as we have seen. Ultimately, understanding these nuances will help you choose the right material for your projects and avoid unpleasant surprises. It is by knowing its characteristics well that you will be able to use it to its best advantage.

Frequently Asked Questions

What exactly is work-hardened copper?

Work-hardened copper is copper that has been hardened by mechanical work, such as hammering or drawing. Imagine bending a paperclip several times: it becomes more rigid. It’s a bit the same principle for work-hardened copper. It is stronger than normal copper, but a little less easy to work with.

Why is work-hardened copper so good at conducting electricity and heat?

Copper is naturally an excellent conductor, a bit like a very smooth highway for electricity and heat. Even when it’s work-hardened, it retains this incredible property. That’s why it’s used a lot in electrical wires or heating systems, as it allows energy to pass through with minimal loss.

Is it difficult to bend or form work-hardened copper?

Yes, work-hardened copper is harder than annealed copper (which is softer). To bend it, you often need to use special tools, like pipe benders, to avoid breaking it or deforming it unexpectedly. It’s a bit like trying to bend a dry branch compared to a green one.

Does work-hardened copper rust?

Copper does not rust like iron. Over time, it develops a beautiful green colour called patina. This layer even protects it from external aggressions. So, no, it does not deteriorate in the same way as iron.

In which fields is work-hardened copper mainly used?

It is widely used in plumbing for pipes, as it is resistant to pressure and corrosion. It is also essential in electrical work for cables and electronic components. Sometimes, it is also used in architecture for decorative elements that need to last a long time.

What is the main difference between work-hardened copper and annealed copper?

The major difference is hardness. Annealed copper is soft and very easy to shape, perfect for complex forms. Work-hardened copper has been made harder and stronger through mechanical work. It is therefore more robust, but requires a little more effort to bend or work with.