In the world of air conditioning and refrigeration, you’ve surely heard of the refrigeration cycle. It’s pretty much the beating heart of all those systems that keep us cool. But how exactly does it work? We’re going to break down how refrigeration works, step by step, so you can finally understand what’s happening behind the cold you enjoy.

Key Takeaways

- The refrigeration cycle uses a fluid that changes state (liquid/gas) due to pressure variations. These changes are key to transferring heat.

- Compression increases the pressure and temperature of the fluid, turning it into vapour. This is the first major step in the refrigeration cycle.

- Condensation, which follows compression, allows the fluid to release its heat to the outside and return to a liquid state. This is where the heat is expelled.

- Expansion reduces the pressure of the liquid, which cools it down and prepares it to absorb heat in the evaporator.

- Evaporation, the final step, allows the cold fluid to absorb heat from the environment to be cooled, thus completing the refrigeration cycle.

The Refrigeration Cycle: Fundamental Principles

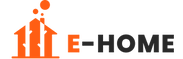

The operation of a refrigeration system relies on a precise thermodynamic cycle, often called the compression cycle. This cycle, which is at the heart of every refrigeration machine, whether it’s an air conditioner or a heat pump, allows heat to be transferred from one place to another. It uses the physical properties of a special fluid, the refrigerant, to accomplish this task. Understanding this cycle is the first step to grasping how cold is produced.

The role of the refrigerant in the cycle

The refrigerant is the central element of any refrigeration system. Its role is to absorb heat in one space and release it elsewhere. To do this, it changes state, moving from liquid to gas and vice versa, thanks to pressure variations. Choosing the right fluid is important, as each type has different characteristics that make it more suitable for certain applications, whether for producing cold or heat. It’s a bit like choosing the right tool for a specific job.

The four key stages of the refrigeration cycle

The refrigeration cycle is broken down into four distinct phases, each taking place in a specific component of the installation: the compressor, the condenser, the expansion valve, and the evaporator. These stages are: compression, condensation, expansion, and evaporation. During these phases, the refrigerant undergoes changes in its pressure, temperature, and physical state (liquid or gaseous). These changes are what enable heat transfer. The change in pressure is the key to the refrigeration system, as it allows the fluid to be in the ideal conditions to capture or release calories.

Here are the four main stages:

- Compression: The gaseous fluid is compressed, increasing its pressure and temperature.

- Condensation: The hot, high-pressure fluid releases heat to the outside and turns into liquid.

- Expansion: The pressure of the liquid is suddenly reduced, which cools it and causes partial vaporisation.

- Evaporation: The cold fluid absorbs heat from the environment to be cooled, completely turning into gas.

Compression and condensation: the heart of the system

In most refrigeration systems, the condensing unit is considered the heart of the system. This is where two of the four essential stages of the cycle take place: compression and condensation. The compressor increases the pressure and temperature of the gaseous refrigerant. Then, in the condenser, this hot, pressurised gas releases its heat to the external environment, thus transforming into liquid. These two processes are therefore intimately linked and constitute an important part of the refrigeration circuit’s operation.

The refrigeration cycle is a continuous process where the refrigerant circulates in a closed loop, changing state and pressure to move heat. Each component of the system plays a precise role to ensure this transfer is efficient.

The Compression Process in Refrigeration

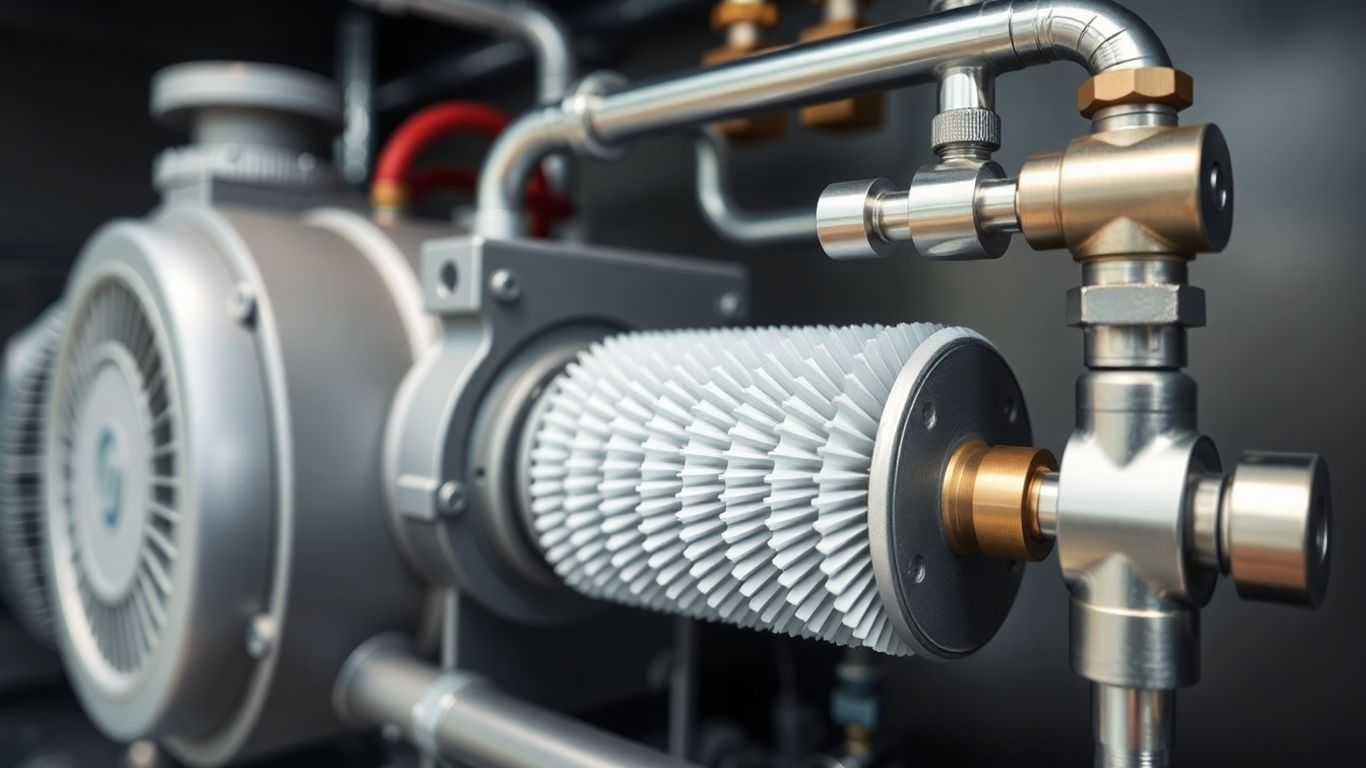

The compressor is truly the engine of the entire refrigeration system. This is where the cycle really begins to take shape. You see, the refrigerant, which at this stage is a low-pressure, low-temperature vapour, is drawn into the compressor. Its job? To compress it.

Increase in fluid pressure and temperature

When you compress a gas, its pressure increases; that’s a physical law. But what also happens is that its temperature skyrockets. Think of a bicycle pump: when you pump air, the pump heats up. It’s the same principle here, but on a much larger scale. The refrigerant exits the compressor as a high-pressure, high-temperature vapour. This is a necessary step for the rest of the cycle to function correctly.

Transformation of gas into superheated vapour

During this compression, the refrigerant changes from a simple gaseous state to what is called a superheated vapour. This means its temperature is well above its boiling point at this new high pressure. This superheating is important because it ensures that the refrigerant remains in a gaseous state when it reaches the condenser, which is essential for the heat transfer that will follow. One could say that this is the beating heart of the system.

Impact on the specific volume of the refrigerant

Another direct effect of compression is the reduction of the refrigerant’s specific volume. Specific volume is the volume occupied by a unit mass of the fluid. By compressing the vapour, you make it denser. Imagine squeezing a balloon: the air inside takes up less space. For the refrigerant, this means it occupies less space for the same amount of mass, which is efficient for transport through the circuit. It’s a bit like optimising space in a home automation system so everything works well.

Here is a summary of the changes during compression:

- Pressure: Increases significantly.

- Temperature: Increases significantly.

- State: Changes from vapour to superheated vapour.

- Specific Volume: Decreases.

Compression is the stage where mechanical energy is converted into thermal and pressure energy for the refrigerant, preparing it for the heat rejection phase.

Condensation: Heat Rejection and Change of State

After passing through the compressor, the refrigerant is at high pressure and high temperature. Its mission in this phase, called condensation, is to get rid of the heat it absorbed in the evaporator. This stage takes place in the condenser.

The role of the condenser in heat evacuation

The condenser acts like a radiator. It is designed to transfer heat from the refrigerant to an external medium, which can be ambient air or water. This heat rejection is essential to allow the fluid to change state. Without this thermal evacuation, the fluid would remain in a gaseous state and the cycle could not continue correctly. The condenser’s ability to dissipate this heat directly influences the overall efficiency of the refrigeration system. It is therefore important to ensure that the condenser is well ventilated or cooled to optimise its performance. You can find information on the different types of refrigerants used in these systems.

The transformation of vapour into liquid

Within the condenser, the refrigerant, which is still in the form of superheated vapour at high pressure, begins to cool down. By giving up its heat, it reaches its saturation point, then condenses. This change of state, from gas to liquid, generally occurs at relatively constant pressure and temperature. This is a key stage where the fluid releases a significant amount of energy in the form of latent heat. The result is a high-pressure liquid, ready for the next stage of the cycle.

Maintaining high pressure and temperature

During condensation, the fluid’s pressure remains high, inherited from the compression stage. Although the temperature decreases as heat is rejected, it remains high enough to allow the change of state. The condenser is sized to handle these high pressure and temperature conditions, thus ensuring stable operation. The fluid leaving the condenser is a high-pressure liquid, often slightly subcooled to improve the efficiency of the subsequent expansion.

Expansion: A Crucial Step for Refrigeration

After condensation, the refrigerant is in liquid form, but it is still at a relatively high pressure and temperature. This is where the expansion stage comes in, a key moment for the cycle to continue and produce cold. Without this phase, the refrigerant would not be able to absorb heat in the evaporator.

Reduction of refrigerant pressure

The main role of the expansion valve is to drastically drop the pressure of the liquid refrigerant. You can imagine this like opening a tap: the liquid goes from a pipe where the pressure is strong to a space where the pressure is much lower. This pressure drop is often achieved by passing the fluid through a calibrated orifice or a capillary tube. This pressure reduction is what prepares the refrigerant for its return to the evaporator.

Partial vaporisation of the liquid

Following this pressure drop, a portion of the liquid refrigerant begins to boil and turns into gas. This phenomenon is called partial vaporisation. The fluid leaving the expansion valve is therefore no longer a pure liquid, but a mixture of liquid and gas. The amount of liquid that vaporises depends on the pressure and temperature conditions before and after the expansion valve. It is an isenthalpic process, meaning that the enthalpy (a measure of the fluid’s total energy) remains constant during expansion.

Modulation of flow to the evaporator

The expansion valve not only reduces pressure; it also acts as a regulator. It controls the amount of refrigerant entering the evaporator. By adjusting this flow, the expansion valve allows the system to adapt to variations in cooling demand. If you need more cooling, the expansion valve will let more fluid pass. If you need less, it will reduce the quantity. This regulation is important for maintaining a stable temperature in the space to be cooled and for optimising the overall operation of the air conditioning system. Good flow management is essential for energy efficiency, much like managing the power supply in your home automation devices to optimise their operation.

The transition from high-pressure liquid to a low-pressure liquid-vapour mixture is a necessary step for the refrigerant to then absorb heat from the environment to be cooled in the evaporator. Without this expansion, the cycle could not be completed.

Evaporation: Heat Absorption and Cooling Cycle

Evaporation is the phase where the refrigerant captures heat from the environment you want to cool. It’s pretty much the moment the system does its main job of producing cold. You’ll see how it works.

The role of the evaporator in heat exchange

The evaporator is a heat exchanger. It is placed in the area you want to cool. Its job is to allow the refrigerant, which arrives as a liquid at low pressure after expansion, to absorb the heat present in that area. It’s a bit like a heat sponge, but for your space. This process is essential for lowering the temperature of the air or water you are trying to cool. The evaporator is therefore the centrepiece of cold production, as this is where heat transfer takes place. It is often compared to the cold source of the refrigeration cycle, as this is where heat is removed. You can find information on the installation of these cooling systems on this website.

Absorption of heat from the medium to be cooled

Once the refrigerant is in the evaporator, it is ready to absorb heat. Imagine you have a lukewarm drink you want to chill. The evaporator acts like the container holding the ice (the cold refrigerant) and the drink. The heat from the drink passes into the ice, causing it to melt and thus cooling the drink. In a refrigeration system, it is the ambient heat (from air, water, etc.) that is absorbed by the refrigerant. This heat absorption causes a change of state in the fluid, making it go from liquid to gas.

Transformation of liquid into gas at low pressure

The passage of the refrigerant from a liquid to a gaseous state in the evaporator is a key step. This change of state occurs at low pressure. When the fluid absorbs heat, it begins to boil, much like water on a hob, but at a much lower temperature. This boiling transforms the liquid into gas. This gas is then drawn into the compressor to restart the cycle. Here are the important points of this phase:

- The refrigerant absorbs heat from the cold source.

- It changes from a liquid to a gaseous state.

- This change of state occurs at low pressure and low temperature.

The efficiency of evaporation depends on the temperature difference between the refrigerant and the medium to be cooled, as well as the evaporator’s exchange surface area.

Enthalpy Diagram and Cycle Operation

To fully grasp how a refrigeration system works, it’s very useful to look at the enthalpy diagram, often called the Mollier diagram. This is a graphical tool that represents the properties of a given refrigerant. It allows you to visualise the different stages of the refrigeration cycle based on enthalpy (the amount of energy per kilogram of fluid) and pressure.

Understanding the Mollier Diagram

The Mollier diagram is specific to each refrigerant. It generally has a bell shape that delineates the areas where the fluid is liquid, vapour, or a mixture of both. The horizontal axis represents enthalpy, which is the total energy contained in the fluid. The vertical axis, meanwhile, indicates pressure. Isothermal (constant temperature) and isentropic (constant entropy) lines are also represented, offering a complete view of the fluid’s states.

Representation of refrigerant states

On this diagram, you can follow the path of the refrigerant through the four main phases of the cycle: compression, condensation, expansion, and evaporation. Each stage corresponds to a change in state, pressure, and temperature. For example, compression increases the enthalpy and pressure of the fluid, transforming it into superheated vapour. Condensation, on the other hand, releases heat and changes the fluid from a vapour to a liquid state at constant pressure.

The Mollier diagram is your map for understanding how the refrigerant behaves and transfers heat throughout the cycle. It helps to visualise energy gains and losses at each stage.

Analysis of pressure and temperature variations

By observing the path on the diagram, you can precisely analyse how the pressure and temperature of the fluid evolve. For example, expansion causes a drastic drop in pressure and, consequently, in temperature, preparing the fluid to absorb heat in the evaporator. Understanding these variations is key to optimising the efficiency of the refrigeration system.

Here is a simplified overview of the stages on a diagram:

- Compression: Increase in pressure and temperature (superheated vapour).

- Condensation: Transition from vapour to liquid at high pressure, heat rejection.

- Expansion: Drop in pressure and temperature.

- Evaporation: Heat absorption, transition from liquid to vapour at low pressure.

Conclusion

You have now covered the key stages of the refrigeration cycle, from compression to evaporation, passing through condensation and expansion. Each component plays a precise role in enabling heat transfer, which is essential for the operation of your air conditioning or refrigeration appliances. Understanding this cycle helps you better grasp how these machines work and the importance of each stage in maintaining a comfortable environment or keeping products cool. Remember that the choice of refrigerant and the proper regulation of these cycles are also crucial for the overall efficiency of the system.

Frequently Asked Questions

What is a refrigeration cycle and how does it work?

Imagine a kind of closed circuit where a special liquid, the refrigerant, travels. This liquid changes state, going from liquid to gas and vice versa, thanks to pressure changes. It’s a bit like when water boils to become steam. These changes of state allow heat to be moved: it absorbs it where you want it to be cold (like in your fridge) and releases it elsewhere, for example outside.

What are the four main stages of a refrigeration cycle?

The cycle unfolds in four main stages. First, compression: the gaseous fluid is compressed, which increases its pressure and temperature. Then, condensation: this hot gas releases its heat to the outside and turns back into liquid. Next, expansion: this liquid passes through a device that reduces its pressure and temperature. Finally, evaporation: the cold liquid absorbs heat from the area to be cooled and turns back into gas, ready to restart the cycle.

What is the role of the compressor in this system?

The compressor is a bit like the engine of the cycle. It takes the refrigerant in the form of low-pressure gas and compresses it very strongly. By doing this, it increases its pressure and temperature, making it ready to release its heat more easily in the next stage, condensation.

Why is condensation important?

Condensation is the stage where the refrigerant, after being compressed and heated, releases the heat it has absorbed. It does this by changing from a gaseous to a liquid state, much like water vapour forming droplets on a cold window. This heat is expelled to the outside, for example by air or water, thus allowing the fluid to cool down.

What is the purpose of the expansion valve?

The expansion valve is a narrow passage that creates a sudden pressure drop for the liquid refrigerant. This pressure drop causes its temperature to fall significantly. This is essential because the fluid must be very cold to be able to absorb heat in the evaporator, which is where the cooling occurs.

How does the Mollier diagram help understand the refrigeration cycle?

The Mollier diagram, also known as an enthalpy diagram, is like a map for the refrigerant. It shows how its temperature and pressure change at each stage of the cycle. By following the fluid’s path on this diagram, one can precisely visualise where it absorbs or rejects heat, and how it changes from gas to liquid and vice versa.