In the world of automation, mastering temperature is a necessity. Whether for a delicate industrial process or to ensure comfort in a building, precise control is essential. This article guides you through the principles of temperature regulation, exploring key components like sensors and actuators, and detailing the operation of the PID algorithm. You will discover how these elements come together to efficiently maintain the desired temperature.

Key Takeaways

- The temperature regulation system relies on a sensor to measure the current temperature, a comparison with the desired temperature (setpoint), and an adjustment by an actuator.

- The PID (Proportional, Integral, Derivative) algorithm is a powerful tool that uses three distinct actions to correct the difference between the measured temperature and the setpoint, ensuring stable and precise regulation.

- Actuators, such as valves or heating elements, are the devices that physically modify the temperature in response to the controller’s commands.

- The choice of a temperature controller depends on the application, the required accuracy, the desired features, and compatibility with the existing system.

- Temperature regulation finds applications in many fields, ranging from building heating and air conditioning to complex industrial processes and electronics.

Fundamental Principles of Temperature Regulation

To master the temperature in a system, one must first understand the basics of its control. It’s a bit like adjusting your home thermostat: you want a certain temperature, and the system must ensure that’s what you get. This involves several key elements working together.

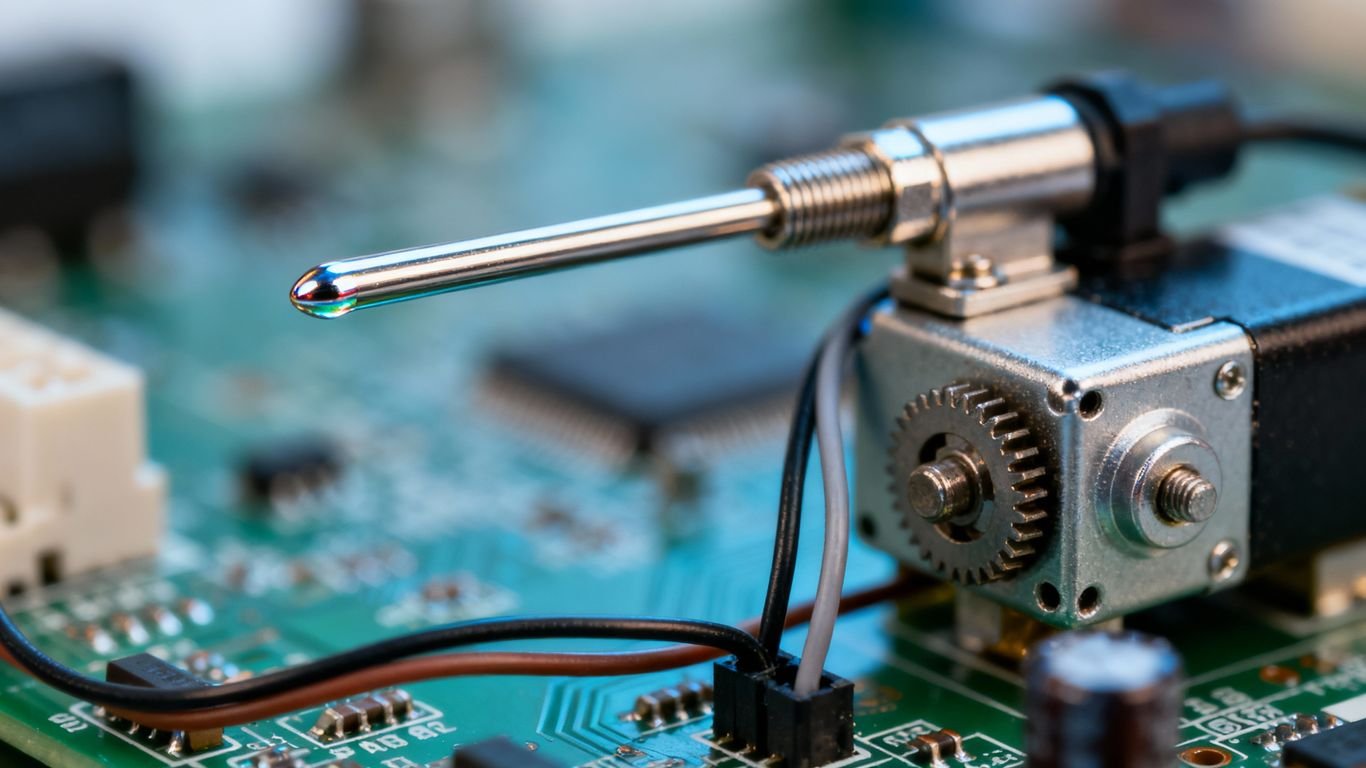

The Role of the Temperature Sensor

The sensor is the eyes and ears of your regulation system. It continuously measures the actual temperature of the environment or process you want to control. Think of it as a very precise thermometer that constantly sends back information. Without this measurement, the controller wouldn’t know if the temperature is too high, too low, or just right. There are different types of sensors, such as temperature probes or thermocouples, each with its own specificities depending on the application and the temperature range to be measured.

Defining the Setpoint Temperature

The setpoint temperature is simply the temperature you want to reach and maintain. It’s your target. You set it directly on the controller. For example, if you set your oven to 180°C, that value is your setpoint temperature. The system will then do everything it can to keep the temperature inside the oven as close as possible to that 180°C.

Comparison and Error Calculation

Once the sensor has measured the current temperature and you have defined the setpoint temperature, the controller comes into play. It compares these two values. The difference between the measured temperature and the setpoint temperature is called the error. It is this error that dictates how the system should react. If the measured temperature is below the setpoint, there is a positive error indicating that heating is needed. If it is above, the error is negative and cooling or stopping heating is required. The precise calculation of this error is the first step for any corrective action.

Here is a simple table to illustrate:

| Measured Temperature | Setpoint Temperature | Error (Measured – Setpoint) |

|---|---|---|

| 22°C | 20°C | +2°C |

| 19°C | 20°C | -1°C |

| 20°C | 20°C | 0°C |

This process of measurement, comparison, and error calculation is at the heart of temperature regulation, and it is often managed by sophisticated algorithms like the PID controller.

Understanding the PID Algorithm

The PID algorithm, an acronym for Proportional, Integral, Derivative, is at the core of many temperature regulation systems. It is a proven method for maintaining a variable (like temperature) at a desired value, called the setpoint, despite disturbances.

Proportional Action and its Band

Proportional action (P) is the controller’s most immediate response. It acts directly on the difference between the measured temperature and the setpoint temperature. The larger this difference, the greater the correction applied by the P action. It’s a bit like turning up the heating more when it’s very cold. However, using only proportional action can lead to oscillations, a phenomenon sometimes called “pumping,” especially in fast-reacting systems. To better control this, the “proportional band” is used.

The proportional band defines the temperature range around the setpoint where the P action is active. If this band is too wide, the system may not react quickly enough. If it’s too narrow, oscillations may occur. Setting this band, often expressed as a percentage of the measurement range or in degrees Celsius, is therefore a key point.

Integral Action to Correct Steady-State Error

Integral action (I) intervenes to eliminate what is called steady-state error. This is the difference that may remain between the measured temperature and the setpoint, even when the system appears to be stabilised. The I action “remembers” past errors and gradually adjusts the controller’s output so that the measured temperature eventually matches the setpoint exactly. It acts on the duration of the error: the longer the error persists, the stronger the integral action becomes. It ensures the long-term accuracy of the regulation.

Integral action is essential for achieving the setpoint value with high precision, especially when the system is subjected to slow changes or variable loads.

Derivative Action to Anticipate Changes

Finally, derivative action (D) adds a touch of anticipation. It analyses the rate at which the temperature is deviating from the setpoint. If the temperature is changing very rapidly, the D action will react more strongly to try and slow down this change before it becomes too significant. This is particularly useful in systems where temperature can vary very quickly, such as in certain industrial processes or ventilation systems. Derivative action helps to avoid overshooting the setpoint and improves the overall stability of the system. However, it can be sensitive to measurement noise, and its use must be cautious to avoid destabilising the system.

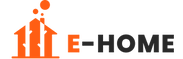

The Role of Actuators in Regulation

After measuring the temperature and calculating the error, the system must be acted upon to correct this deviation. This is where actuators come in. Without them, your controller would be a brain without arms, incapable of changing anything.

There is a variety of actuators, each suited to specific needs. They can be classified by their mode of action or their energy source.

- Motorised control valves: Often used to control the flow of a fluid (hot water, steam, air). They can be proportional (for fine adjustment) or on/off. Their movement is usually provided by an electric motor or a servomotor.

- Electric heating elements: Such as heating resistors in an oven or radiator. Their power can be modulated by solid-state relays (TRIACs) or contactors.

- Fans and pumps: Their speed can be adjusted to modify the flow of air or liquid, thus influencing heat transfer.

- Compressors and expansion valves: Essential in refrigeration systems, they adjust the thermodynamic cycle to cool or heat.

The choice will depend on the power to be supplied, the required precision, and the type of energy available.

Interface Between Controller and Actuator

The controller, whether a simple thermostat or a sophisticated PID controller, communicates its instructions to the actuator via a signal. This signal can take several forms:

- On/Off signal: The actuator is either fully activated or fully deactivated. This is the simplest mode, but it offers little precision.

- Analogue signal: Commonly, signals such as 0-10V or 4-20mA are used. These signals allow for continuous variation of the actuator’s power or position, thus offering finer control.

- Digital signal: With modern systems, digital communication protocols (such as Modbus, Profibus) allow for richer information exchange between the controller and the actuator, including diagnostics and configuration parameters.

Compatibility between the controller’s output signal and the actuator’s input is absolutely crucial for correct operation.

Impact of the Actuator on System Dynamics

The actuator is not a mere executor; it directly influences how the system reacts to changes. Its response speed and capacity (the maximum power it can deliver) are key parameters.

An actuator that is too slow or undersized will not be able to follow the corrections requested by the controller, leading to oscillations or an inability to reach the setpoint. Conversely, an actuator that is too reactive or oversized can make the system unstable if the controller is not properly tuned.

Here are some aspects to consider:

- Rise time: The time it takes for the actuator to go from 0% to 100% of its capacity.

- Linearity: The relationship between the control signal and the actuator’s response should be as linear as possible to facilitate controller tuning.

- Hysteresis: Some play or difference in response between an increasing and decreasing command may exist, especially in mechanical valves.

Understanding these characteristics will help you choose the right actuator and tune your regulation system optimally.

Implementation and Selection of a Temperature Controller

Choosing the right temperature controller for your application can seem complex, but by following a few key steps, you can make an informed decision. It’s not just about finding a device that displays numbers; you need to ensure it integrates well with your system and precisely meets your needs.

Selection Criteria for a Specific Application

To begin, you need to clearly define your needs. Ask yourself the right questions: what is the exact temperature range you need to control? Do you need accuracy to the tenth of a degree, or is a wider margin acceptable? The nature of your application is also important: is it for heating, cooling, maintaining a stable temperature, or following a complex temperature profile?

Here are some points to consider:

- Temperature range: Define the minimum and maximum temperatures the system will need to handle.

- Required accuracy: Determine the acceptable tolerance for the difference between the measured temperature and the setpoint.

- Process type: Heating, cooling, mixing, drying, etc. Each process has different dynamics.

- Operating environment: Ambient conditions (humidity, dust, vibrations) can influence the choice of equipment.

There are different types of controllers. ON/OFF controllers are the simplest and cheapest, perfect for applications where slight temperature variations are not a problem. For finer regulation, PID controllers are the standard. They offer much higher stability and accuracy. If your needs change often, a programmable controller might be more suitable.

Advanced Features of Modern Controllers

Today’s controllers go far beyond simple measurement and control. Many features can simplify your work and improve your system’s performance. Alarms are common: they alert you if the temperature goes outside the limits you’ve set, which is vital for product or process safety. Communication capability is also increasingly important. Being able to connect your controller to a supervision system (like a BMS or a GTC) or other equipment allows for centralised management and better responsiveness.

Some controllers can also record temperature data over a given period. This is very useful for performance analysis, regulatory compliance, or batch traceability. Also consider programming options: some controllers allow you to define complex temperature cycles, useful for processes like baking or drying.

Installation and Compatibility Considerations

Once you have an idea of the type of controller and the features you need, you must verify that it will integrate well with your existing installation. Compatibility with your sensors and actuators (heating, valve, etc.) is paramount. Ensure that the controller’s output signals match your actuators’ inputs (e.g., 0-10V, 4-20mA, or digital communication).

The installation itself must be considered. Does the controller mount easily in your electrical panel? Do you need technical support for wiring or initial configuration? Don’t forget to factor in the total cost, which includes not only the purchase but also installation, commissioning, and future maintenance. A cheaper device to buy may cost more in the long run if it’s difficult to install or maintain.

The selection of a temperature controller is not limited to its intrinsic performance. It is imperative to assess its ability to integrate harmoniously into the existing technical ecosystem and anticipate the constraints related to its physical deployment and maintenance.

Common Applications of Temperature Regulation

Temperature regulation is not just a matter for laboratories or heavy industry. You find it everywhere, often without even thinking about it. It guarantees comfort, safety, and efficiency in a multitude of fields. Let’s look at some concrete examples where this technology plays a key role.

Heating, Ventilation, and Air Conditioning (HVAC) Systems

In your home or office, the HVAC system is probably the most familiar application of temperature regulation. The thermostat you use to set the ambient temperature is, in fact, a temperature controller. It measures the room temperature and commands the heating or air conditioning system to reach and maintain the setpoint temperature you have chosen. The goal is simple: ensure your thermal comfort while optimising energy consumption. Without precise regulation, your system could overheat or underheat, leading to discomfort and wasted electricity or gas.

- Continuous measurement: A temperature sensor in the thermostat constantly assesses the room temperature.

- Comparison: This measurement is compared to the temperature you have set (the setpoint).

- Corrective action: If a difference is detected, the controller turns the heating or air conditioning on or off.

- Maintenance: The system continues to adjust power to stay as close as possible to the desired temperature.

The accuracy of these systems has become increasingly important, not only for comfort but also for reducing the energy footprint of buildings.

Industrial and Manufacturing Processes

In industry, temperature regulation is often much more critical. It can be the key to product quality, operational safety, or the efficiency of a chemical reaction. Consider plastic manufacturing, ceramic firing, food production, or chemical reactions. In these contexts, even minor temperature deviations can have disastrous consequences: a production batch may be rejected, equipment may be damaged, or a reaction may become dangerous.

Here are some examples of industrial applications:

- Industrial ovens: Maintaining very precise temperatures for baking, drying, or heat treatment of materials.

- Chemical reactors: Strict temperature control to ensure the safety and yield of reactions.

- Storage of sensitive products: Maintaining stable temperature conditions for pharmaceuticals, foodstuffs, or electronic components.

- Polymer extrusion: Fine temperature regulation to achieve the desired viscosity and properties of the plastic.

| Application | Typical Temperature | Required Accuracy | Actuator Type |

|---|---|---|---|

| Ceramic firing | 1000-1400 °C | ± 5 °C | Heating resistors |

| Pharmaceutical storage | 2-8 °C | ± 1 °C | Refrigeration |

| Chemical reaction | Variable | ± 0.5 °C | Control valves |

Consumer Electronics and Automotive

Even in the devices you use every day, temperature regulation is at work. In your computer or smartphone, fans and heat sinks are managed by controllers to prevent overheating of electronic components. Too high a temperature can reduce the lifespan of these components, or even damage them. In the automotive sector, temperature regulation is also ubiquitous: engine management, cabin climate control, electric vehicle batteries, and even braking systems. The proper functioning of many systems directly depends on controlled temperature.

- Computers and game consoles: Control of fans to keep processors and graphics cards at optimal temperatures.

- Electric vehicles: Thermal management of batteries to optimise their performance and longevity.

- Refrigerators and freezers: Maintaining low temperatures for food preservation.

- Automotive air conditioning systems: Ensuring passenger comfort regardless of external conditions.

Technological Advancements in Temperature Regulation

Temperature regulation, while rooted in proven principles, is constantly being transformed by technological advancements. These innovations aim to improve the accuracy, efficiency, and adaptability of thermal control systems.

Adaptive and Predictive PID Controllers

Classic PID controllers, while effective, can sometimes struggle with systems whose characteristics change over time. This is where adaptive controllers come in. These systems automatically adjust their parameters (P, I, D) to maintain optimal performance, even when conditions vary. Imagine an industrial oven whose load changes frequently; an adaptive PID will adjust without manual intervention.

In parallel, predictive control uses mathematical models of the system to anticipate its future behaviour. Instead of simply reacting to the current error, it predicts upcoming deviations and takes corrective action before they even occur. This helps to reduce overshoots and reach the setpoint temperature faster and with more stability. The history of regulation shows constant evolution, from the first pneumatic controllers like those developed by Taylor Instrument Companies in 1939, to today’s intelligent systems.

Integration of Artificial Intelligence

Artificial intelligence (AI) and machine learning are opening up exciting new possibilities. These technologies allow controllers to learn from historical data and continuously optimise their algorithms. They can identify complex patterns and adjust control strategies more finely than a human could. For example, an AI-based system could learn to minimise energy consumption while maintaining the desired temperature, taking into account factors like electricity prices or weather forecasts.

AI does not replace the fundamental principles of PID, but it complements them by providing unprecedented learning and adaptation capabilities, making regulation systems more autonomous and efficient.

Connectivity and Remote Monitoring (IoT)

The advent of the Internet of Things (IoT) is radically transforming how we interact with temperature regulation systems. It is now possible to monitor and control these systems remotely, via mobile apps or web interfaces. This connectivity offers several major advantages:

- Real-time monitoring: Access temperature data and system status from anywhere.

- Customised alerts: Receive instant notifications in case of problems or threshold breaches.

- Remote diagnostics: Allows technicians to identify and sometimes resolve issues without travelling.

- Data collection: Facilitates the recording and analysis of data for process optimisation and regulatory compliance.

This remote monitoring is particularly useful for geographically dispersed installations or for environments where constant physical access is difficult. The ability to integrate these controllers into centralised building management systems (BMS) or technical building management (TBM) allows for global and optimised infrastructure management.

Conclusion

There you have it, you now have a better idea of how sensors, actuators, and especially PID control work to regulate temperature. It’s a very widespread system, whether in your home for heating or in factories for complex processes. Choosing the right equipment and tuning it properly can really make a difference. Remember that even as technology evolves, the basics remain the same: measure, compare, act. If you have a project in mind, think about clearly defining your needs to make the most suitable choice. By understanding these principles, you can optimise your systems and achieve the desired results.

Frequently Asked Questions

How does a basic temperature controller work?

Imagine you want to keep your room at 20°C. A temperature controller does this: a sensor measures the current temperature. Then, it compares this measurement to the temperature you want (the setpoint, here 20°C). If the temperature is too low, the controller sends a signal to turn on the heating. If it’s too hot, it sends a signal to turn it off or turn on the air conditioning. It’s like a thermostat, but often smarter.

What is the PID algorithm and why is it important?

PID stands for Proportional, Integral, Derivative. It’s a widely used method for precisely controlling temperature. The ‘Proportional’ action reacts to the current error. The ‘Integral’ action corrects small errors that persist for too long. The ‘Derivative’ action anticipates rapid changes to prevent overshoots. Together, they help maintain a stable temperature without too much jerky movement.

What is the role of actuators in temperature regulation?

Actuators are the ‘muscles’ of the system. They receive commands from the controller (which uses PID, for example) and actually act on the temperature. For instance, an actuator could be a valve that opens or closes to let hot water through, or a heating element that turns on or off. Without actuators, the controller couldn’t change the temperature.

How do I choose the right temperature controller for my needs?

To choose well, ask yourself a few questions: What temperature do I need to control? Do I need high precision? What is the size of the room or system to be regulated? Is it for heating, cooling, or both? Simple (ON/OFF) controllers are sometimes sufficient, but for greater accuracy, a PID controller is often better. Also, check if it has useful features like alarms or the ability to connect to a computer.

Where is temperature regulation most commonly found?

Temperature regulation is everywhere! Think of heating and air conditioning systems in homes and offices (HVAC). It’s also essential in factories for manufacturing products (like in the food or chemical industries), in cars for the engine or air conditioning, and even in your everyday appliances like refrigerators or ovens.

Is temperature controller technology evolving?

Absolutely! Controllers are becoming increasingly intelligent. Some can automatically adjust their settings if conditions change (adaptive PID). Others use artificial intelligence to learn and become even more efficient. Furthermore, many can now be monitored and controlled remotely via the Internet (IoT), which is very convenient.